Windpark Zuidwester

Construction wind farm Zuidwester

innogy SE (NewCo)

ListRWE is constructing the wind farm with a planned total capacity of 90 megawatts along the dykes of the IJsselmeer. The electrical energy generated here will be sufficient to supply the equivalent of 90,000 households per year with green electricity.

122,68 MB 720p

test offshore installation vessel

test installation vessel Seabreeze

innogy SE (NewCo)

ListFor the logistics demand of offshore wind farms RWE Innogy has commissioned two special installation vessels. They will overcome one of the most important supply bottlenecks RWE Innogy faces in the construction of wind farms at sea.

The vessels are able to transport and install up to four of the largest available offshore wind turbines including foundations. Featuring satellite control, these ships can be fixed with centimetre-precision for construction work at sea and operate in water depths of more than 40 metres. The first two vessels are intended to be completed in 2011.

A first part of the vessel – the leg point. With a length of 100 metres and a width of 40 metres, the vessels will be counted among the major installation vessels worldwide. One of them is built for the construction of the wind farms in the German part of the North Sea. Of the Welsh coast, the other vessel will be needed for the construction of an offshore wind farm to be called "Gwynt y Môr". The order value per vessel is approx. EUR 100 million.

160,43 MB 720p

wind farm

offshore wind farm, North Hoyle, Liverpool Bay, UK, Fynnon Oer wind farm Neath, UK

-

innogy SE (NewCo)

ListNorth Hoyle is the UK’s first major offshore wind farm and represents a major milestone in the UK’s drive towards cleaner sources of power. Built in 2003, the project is now fully operational and produces enough clean, green electricity each year to meet the needs of approximately 40,000 homes.

The project is located 4-5 miles off the North Wales coast between Rhyl and Prestatyn and comprises 30 wind turbines, each rated at 2 MW.

267,39 MB 576p

Offshore installation vessel: Loading

Loading of components for the offshore wind farm to ship

innogy SE (NewCo)

ListFootage, loading of components for the offshore wind farm on the offshore installation vessel. Port facility with ships and cranes.

357,56 MB 1080p

Nordsee Ost offshore wind farm – Project movie

Movie about the construction of the Nordsee Ost Offshore wind farm

innogy SE (NewCo)

ListAfter completion and start of commercial operations in summer 2015, the Nordsee Ost offshore wind farm will have installed power of around 295 megawatts and supply the equivalent of around 320,000 households with electricity. Equipped with the presently most powerful offshore turbines, Nordsee Ost is one of the biggest commercial wind farm projects off the German coast.

189,79 MB 720p

offshore wind farm Rhyl Flats

Film about the construction of offshore wind farm Rhyl Flats

-

innogy SE (NewCo)

ListIn December 2009 RWE Innogy officially opened Rhyl Flats Offshore Wind Farm in North Wales.

The wind farm is situated five miles off the north Wales coast, in Liverpool Bay. With an installed capacity of 90 megawatts (MW), Rhyl Flats is the biggest Welsh power station producing energy from renewable sources. Its 25 wind turbines will power the equivalent of 61,000 households per year and save several tens of thousands of tonnes of carbon emissions.

Rhyl Flats is RWE’s second offshore wind farm. The project was developed by a company called Celtic Offshore Wind Limited (COWL) who received full consents in 2002 to build and operate the scheme. RWE npower renewables purchased the Rhyl Flats project from COWL in December 2002 and we are now constructing the wind farm.

In 2006, we carried out site investigation works on the area of seabed where the Rhyl Flats Offshore Wind Farm turbines will be located. The works comprised drilling boreholes and taking samples of the seabed using a jack-up barge vessel.

In July 2007, offshore foundation construction at the Rhyl Flats Offshore Wind Farm site began with installation of the scour protection, based out of the Port of Mostyn in Flintshire. The works involved the laying of rocks on the seabed at the turbine locations on the wind farm site. The rocks, which have been sourced from the Penrhyn Slate Quarry near Bangor, Gwynedd, will prevent localized erosion of the seabed around the turbine foundations.

Installation of the foundation piles themselves began in April 2008, and was completed in July 2008, when the offshore cabling installation commenced. The first of the cables to be installed were the three export cables between the beach and the wind farm. All offshore construction was suspended from 15th December 2008 in line with environmental consent conditions, and recommenced on 1 April 2009. The onshore electrical substation has since been completed and the grid connection made.

148,9 MB 576i

Nordsee offshore wind farm – Cable & Substation

Cable laying works and installation of the substation at sea

innogy SE (NewCo)

ListAll 48 wind turbines were connected with each other by so-called inter-array cables and linked to a substation. Altogether, this required more than 60 kilometres of cables. The 33-kilovolt underwater cables have a diameter of up to 16 centimetres. A particularly robust sheath protects them from the extreme stresses caused in particular by the installation process out at sea. At the same time, they guarantee maximum power transmission across large distances. These high-performance power lines were installed by special-purpose cable-laying vessels.

The offshore substation is the nerve centre of the wind farm. It transforms the electricity generated by the wind power systems at 33 kilovolt (kV) to a transmission voltage of 155 kV. High-voltage submarine cables transmit the electricity from here to the coast. Such an offshore substation is about 18 metres high and weighs approx. 2,100 tons. Like the wind turbines, it is mounted on top of a steel structure foundation in the sea bed and juts out approx. 37 metres above the sea level after final assembly. The electricity generated by the individual wind power systems is pooled in the offshore substation before it is transmitted to the nearest grid connection point through high-voltage subsea cables.

After completion and start of commercial operations in spring 2015, the Nordsee Ost offshore wind farm will have installed power of around 295 megawatts and supply the equivalent of around 320,000 households with electricity. Equipped with the presently most powerful offshore turbines, Nordsee Ost is one of the biggest commercial wind farm projects off the German coast.

609,22 MB 1080p

Nordsee Ost offshore wind farm – Commissioning of the wind turbines

Commissioning and rotating wind turbines

innogy SE (NewCo)

ListAfter completion and start of commercial operations in summer 2015, the Nordsee Ost offshore wind farm will have installed power of around 295 megawatts and supply the equivalent of around 320,000 households with electricity. Equipped with the presently most powerful offshore turbines, Nordsee Ost is one of the biggest commercial wind farm projects off the German coast.

84,31 MB 1080p

offshore installation vessel

Different perspectives of the vessel, helicopter shots and sail away (transport from korea to Germany)

innogy SE (NewCo)

ListFor the construction of offshore wind farms RWE is operating two special-purpose installation vessels. With a length of over 100 metres and a width of 40 metres, these vessels are among the largest of their kind in the world. For the construction work at sea, these vessels are controlled by satellites and can be positioned to an accuracy of centimetres. For this purpose, they have extendable steel legs which hold the vessels firmly in place on the sea bed. This transforms the vessel to a jack-up platform from which foundations can be placed and wind turbines be installed. One of these vessels is deployed from Bremerhaven for the construction of Nordsee Ost.

127,93 MB 1080p

Offshore installation vessel: Transportation

Offshore installation ship sails out to sea to the construction site

innogy SE (NewCo)

ListOffshore installation vessel is towed by tugs from the port. Journey to the sea to the construction site.

188,74 MB 1080p

Offshore installation vessel: Installation of a jacket foundation

Offshore installation vessel installs the wind turbine

innogy SE (NewCo)

ListOffshore installation vessel installed the base of the wind turbine on the high seas. Certain work processes are shown in fast motion.

532,68 MB 1080p

Nordsee offshore wind farm - Installation of the wind turbines (part 1)

Installation of a tower section and a nacelle

innogy SE (NewCo)

ListWind power systems of the turbine manufacturer Senvion will be used for the Nordsee Ost offshore wind farm. The state-of-the-art offshore plant of the multi-megawatt class has a capacity of almost 6 megawatts. The tower of the plant is 70 metres high and weighs 243 tons. The nacelle has a weight of approx. 350 tons. It accommodate machine components like transmission and generator. The three rotor blades sweep a surface area of 126 meters, equivalent roughly to the size of two football fields. All rotor blades come with a total weight of some 125 tons.

After completion and start of commercial operations in spring 2015, the Nordsee Ost offshore wind farm will have installed power of around 295 megawatts and supply the equivalent of around 320,000 households with electricity. Equipped with the presently most powerful offshore turbines, Nordsee Ost is one of the biggest commercial wind farm projects off the German coast.

344,98 MB 1080p

computer animation RWE Innogy offshore installation vessel

Animation - RWE Innogy Offshore installation vessel

innogy SE (NewCo)

ListFor the logistics demand of offshore wind farms RWE Innogy has commissioned two special installation vessels. They will overcome one of the most important supply bottlenecks RWE Innogy faces in the construction of wind farms at sea.

The vessels are able to transport and install up to four of the largest available offshore wind turbines including foundations. Featuring satellite control, these ships can be fixed with centimetre-precision for construction work at sea and operate in water depths of more than 40 metres. The first two vessels are intended to be completed in 2011.

A first part of the vessel – the leg point. With a length of 100 metres and a width of 40 metres, the vessels will be counted among the major installation vessels worldwide. One of them is built for the construction of the wind farms in the German part of the North Sea. Of the Welsh coast, the other vessel will be needed for the construction of an offshore wind farm to be called "Gwynt y Môr". The order value per vessel is approx. EUR 100 million.

158,33 MB 720p

Nordsee offshore wind farm - Installation of the wind turbines (part 2)

Loading and installation rotor blades (Rotor star assembly)

innogy SE (NewCo)

ListThe installation of the 48 wind turbines took place from the base port in Bremerhaven. Like the foundations, the tower segments, nacelles and rotor blades were also stored, pre-assembled and loaded on the installation vessels “Victoria Mathias” and “Friedrich Ernestine” at the Eurogate Container Terminal.

The individual components of the 6-megawatt turbines from Senvion impress through their huge dimensions: With around 160 metres from sea level to the tip of the blade, the wind turbine stands higher than Cologne Cathedral. The nacelle has a weight of approx. 350 tonnes and the dimensions of a detached house. Inside the nacelle are the machine components like gearbox and generator. The tower consisting of two individual segments is in total over 70 metres long and weighs over 240 tonnes. The individual rotor blades are 60 metres long and weigh approx. 23 tonnes. This equates to the weight of about six fully-grown elephants.

After completion and start of commercial operations in spring 2015, the Nordsee Ost offshore wind farm will have installed power of around 295 megawatts and supply the equivalent of around 320,000 households with electricity. Equipped with the presently most powerful offshore turbines, Nordsee Ost is one of the biggest commercial wind farm projects off the German coast.

468,71 MB 1080p

1st Generation, Gwynt y Mor Offshore Wind Farm

High quality raw footage describing first generation at Gwynt y Môr Offshore Wind Farm, off the North Wales coast.

Toby Edmonds, Stuart Selwood, Ben Rose

innogy SE (NewCo)

ListThe footage includes clips from Toby Edmonds, Project Director of Gwynt y Môr Offshore Wind Farm, Stuart Selwood, Commissioning Manager at Gwynt y Môr Offshore Wind Farm and Ben Rose, wind turbine technician (in Welsh). In addition there are general views of the first generating turbine (F13F), GVs of the offshore construction site, offshore substation, export cable works and onshore substation.

284,16 MB 1080p

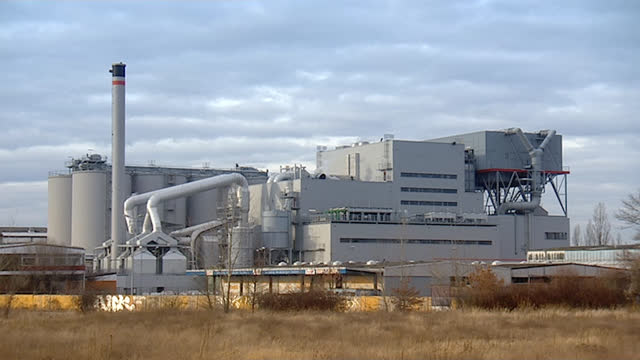

wood-fired power station

wood-fired power station, Berlin- Gropiusstadt, germany

innogy SE (NewCo)

ListOur most recent facilities partly involve the use of untreated wood, i.e. residual forestry wood and landscape conservation wood, whilst in the medium term we are planning to use fuel wood from short-rotation plants. Under the German Clean Air Act, the firing system where these fuels are used must ensure that no pollution occurs even when the wood has a high water content. For economic and environmental reasons we want to build such plants reasonably close to the actual wood crops.

Depending on the size of a plant, we use a range of different firing techniques. If the thermal output is high, we prefer firing systems with circulating or atmospheric fluidised beds, whereas with smaller units we rely on grate furnaces.

Our existing biomass-fired cogeneration plants are largely based on the efficient combination of heat and power generation. This is where we burn used wood in categories AI – AIV. As fractions AIII and AIV are contaminated, our focus has been particularly on the combustion process and on flue gas purification. We therefore obtained approval for our facilities under the 17th Ordinance Implementing the Federal Immission Control Act. To prevent corrosion, the heating surfaces in the boiler need to be arranged in a certain way.

112,2 MB 576p

biomass-fired power plant

biomass-fired power plant, Kehl, Germany

-

innogy SE (NewCo)

ListAs a leading company in the local production of energy, we have had many years of experience in the construction and operation of facilities that use biomass for energy purposes.

Our most recent facilities partly involve the use of untreated wood, i.e. residual forestry wood and landscape conservation wood, whilst in the medium term we are planning to use fuel wood from short-rotation plants. Under the German Clean Air Act, the firing system where these fuels are used must ensure that no pollution occurs even when the wood has a high water content. For economic and environmental reasons we want to build such plants reasonably close to the actual wood crops.

Depending on the size of a plant, we use a range of different firing techniques. If the thermal output is high, we prefer firing systems with circulating or atmospheric fluidised beds, whereas with smaller units we rely on grate furnaces.

Our existing biomass-fired cogeneration plants are largely based on the efficient combination of heat and power generation. This is where we burn used wood in categories AI – AIV. As fractions AIII and AIV are contaminated, our focus has been particularly on the combustion process and on flue gas purification. We therefore obtained approval for our facilities under the 17th Ordinance Implementing the Federal Immission Control Act. To prevent corrosion, the heating surfaces in the boiler need to be arranged in a certain way.

155,19 MB 576p

biogas plant

biogas plant Grevenbroich, Germany

-

innogy SE (NewCo)

ListRWE Innogy currently operates two biogas plants in Germany. Since May 2007, a biogas plant near Neuss has been supplying 1,600 residential households with electricity and an adjacent factory with heat. Local farmers deliver approximately 38 tonnes of renewable raw materials and liquid manure to the plant every day. We have also built a further improved plant at Güterglück in eastern Germany. Since 2009, the facility has been producing 15,000 cubic metres of biogas a day, which is processed to the same standard as natural gas and then fed into the local natural gas network. That amounts to a total gas production equivalent to 50,000 megawatt hours a year. Using this approach, biogas can be fed to decentralised cogeneration sites located some distance from the actual plant and then used locally with an efficiency rate of over 90 per cent. The knowledge we have gained from these facilities is for example being put to good use in a new biogas plant in Bergheim-Paffendorf, where it is also planned to feed 15,000 cubic metres of processed biogas a day into the public grid.

374,34 MB 576p

Triton Knoll – Partnership deal RWE & Statkraft – Joint statement

RWE & Statkraft explain the reasons behind the 50:50 partnership deal

innogy SE (NewCo)

ListRWE Innogy and Statkraft have signed an agreement to jointly develop the Triton Knoll Offshore Wind Farm, off the east coast of England. The deal will see Statkraft take a 50% stake in the UK wind farm, which has an expected capacity of up to 900MW.

177,21 MB 720p

Triton Knoll - Partnership RWE & Statkraft – Statement Hans Bünting

Hans Bünting, CEO RWE Innogy explains details of the 50:50 partnership arrangement

innogy SE (NewCo)

ListRWE Innogy and Statkraft have signed an agreement to jointly develop the Triton Knoll Offshore Wind Farm, off the east coast of England.

The deal will see Statkraft take a 50% stake in the UK wind farm, which has an expected capacity of up to 900MW. Hans Bünting, CEO RWE Innogy explains details of the 50:50 partnership arrangement

122,68 MB 720p

Triton Knoll - Partnership RWE & Statkraft – Statement Jacob Hain

Jacob Hain discusses the details of the 50:50 partnership arrangement with Statkraft

innogy SE (NewCo)

ListJacob Hain discusses the details of the 50:50 partnership arrangement with Statkraft

104,33 MB 720p